Optical Alignments

OPTICAL ALIGNMENT SERVICES

Accurate to .001" over a distance of 17 feet

Unlike most alignment service providers, GLASS uses a variety of alignment techniques as a solution to today’s demanding machinery tolerances:

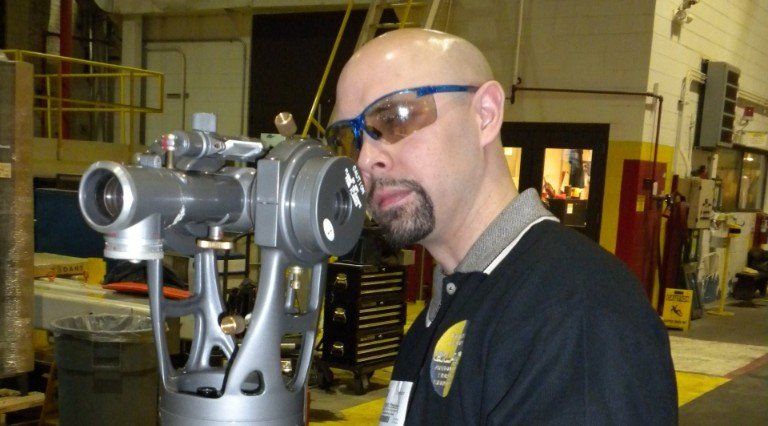

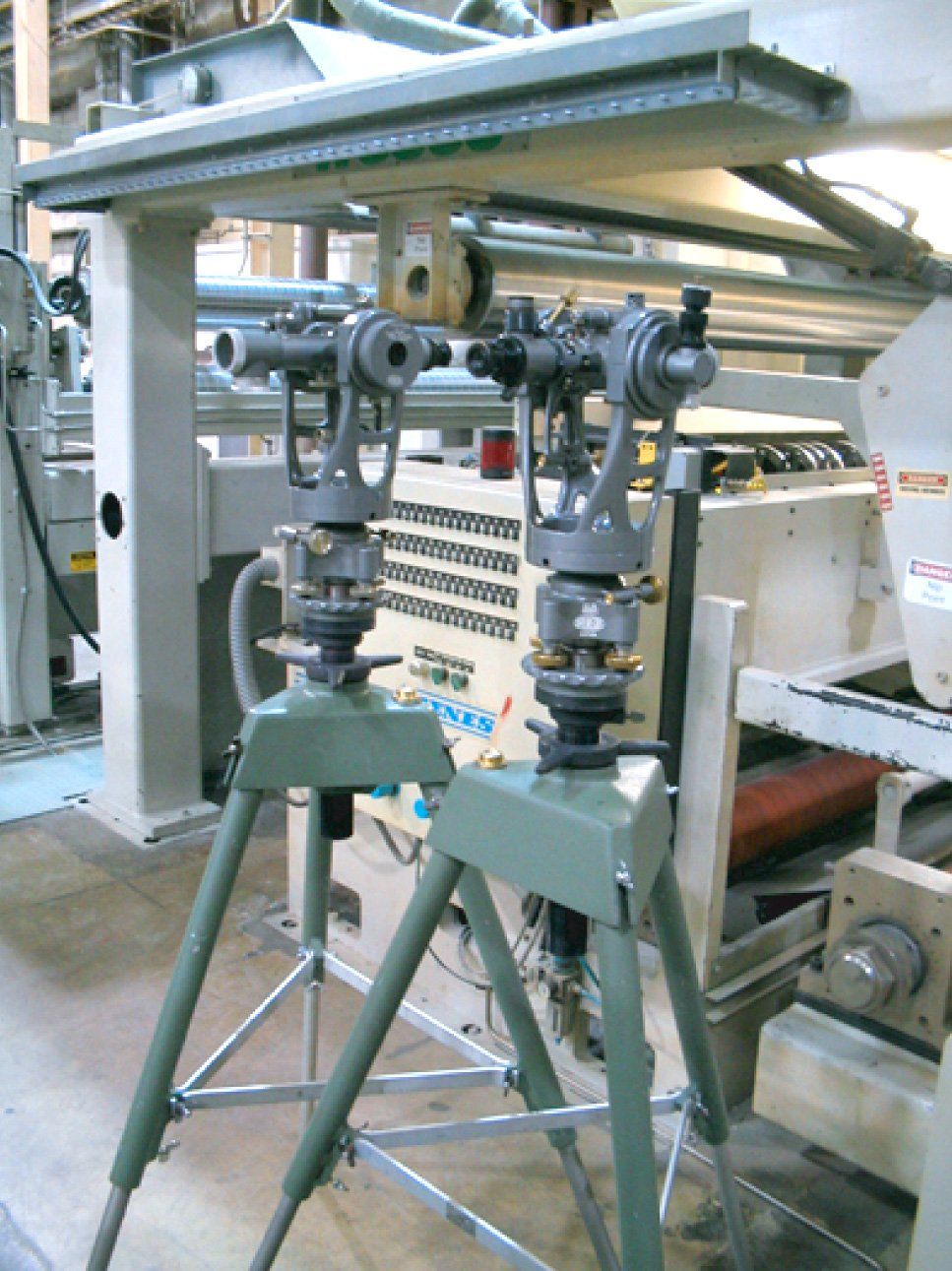

Precise Optical Tooling

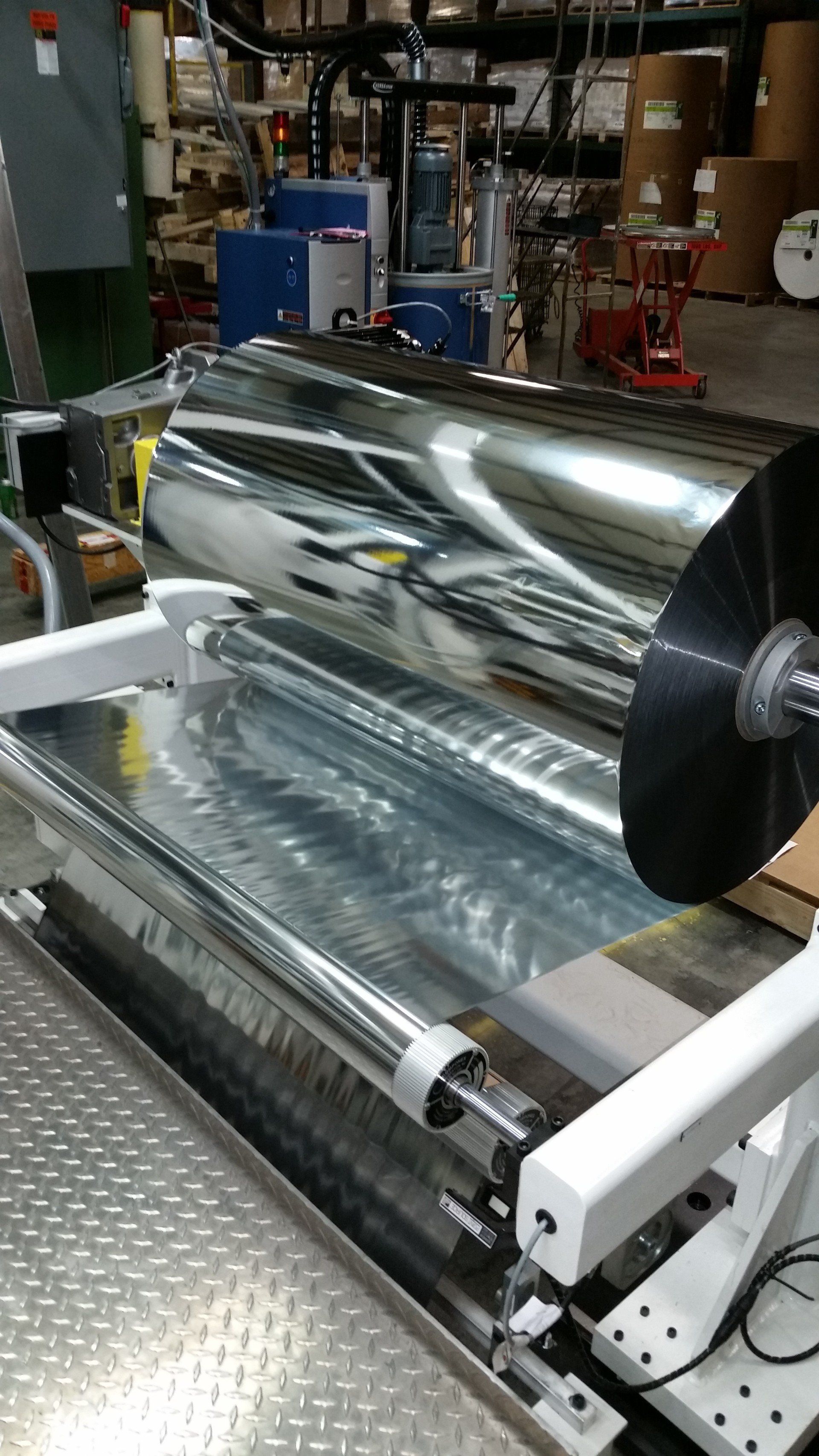

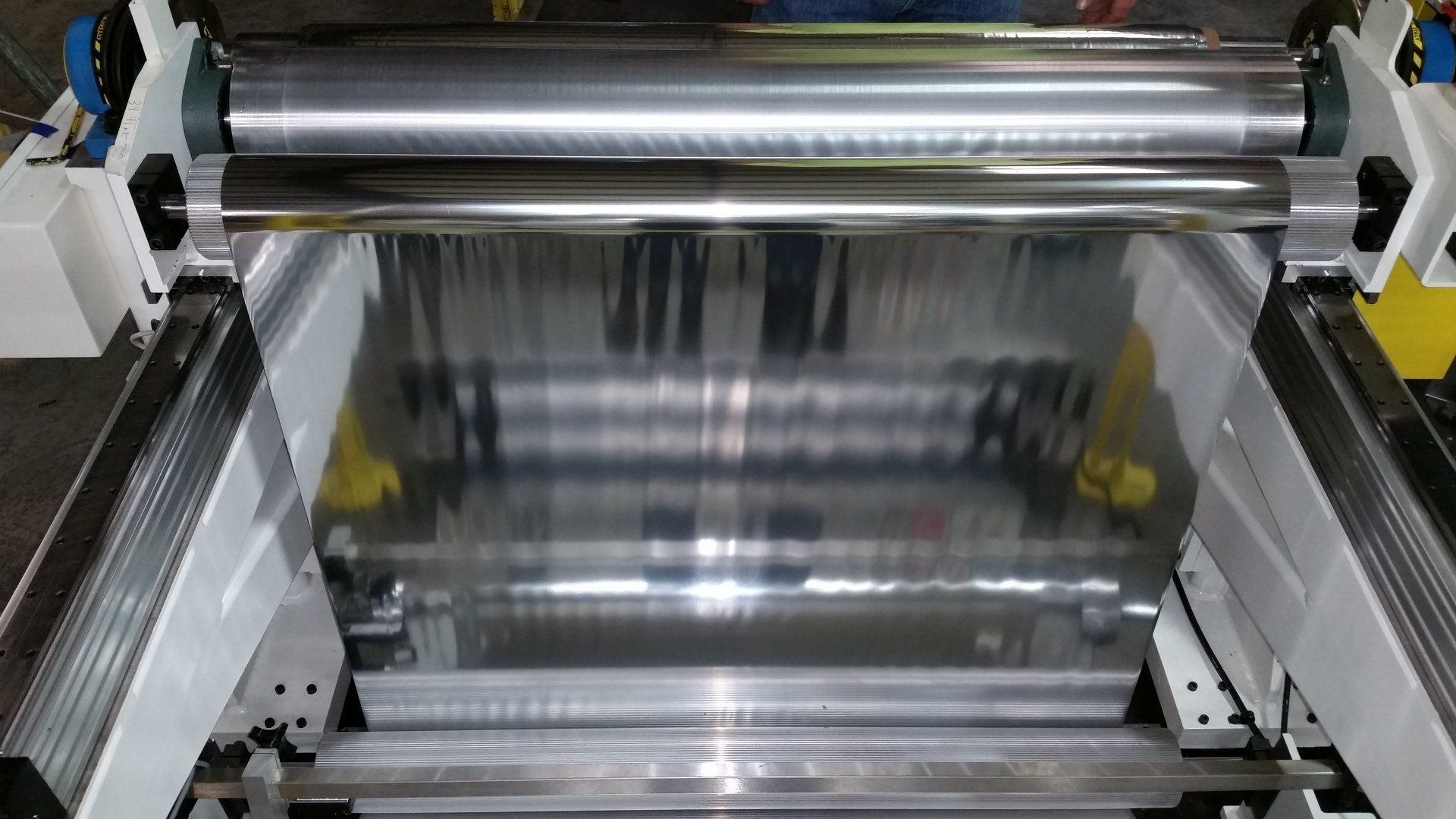

We use precise optical alignment equipment, such as Brunson Transits and Sight Levels. This optical equipment is accurate to 0.001” over a distance of 17 feet. Optics are the workhorse of the alignment industry due to their versatility and short setup time. GLASS prefers the use of Optics when it comes to machinery installation or roller alignment. We successfully align our customers' machinery to a tolerance of 0.001” to help optimize machine performance.

Optics is our preferred choice for Machinery Installation or Roller Alignment

Optical alignment has the advantage of using a common reference, such as the machine centerline, to eliminate compounding of errors that occur when using tramming rods, or pi tapes. Each roll or machine component that is inspected with optics is done using a control scope that is not moved and a secondary scope that is used to inspect the component in question. Therefore separate components, up to hundreds of feet away from each other, can be inspected using the same datum, providing accurate alignment information.

OTHER

ALIGNMENTSERVICES

ALIGNMENT

LASER TRACKER ALIGNMENT

We use the Faro Laser Tracker with accuracy to 72 microns over a distance of 20 ft.

LASER SHAFT ALIGNMENT

We use the Rotalign Pro technology with accuracy up to .0004" over a distance of 33 ft.

MENU

GET IN TOUCH

Great Lakes Alignment Survey Services, LLCW7036 Rimrock Ln Greenville, WI 54942

GLASS understands the need to keep any information that you share with us confidential. We will protect any information that you share with us and never share that information with another person, party or entity.

Great Lakes Alignment Survey Services. All Rights Reserved.